Exploring the Applications of EPS Sandwich Panel Machine

What Are the Primary Applications of an EPS Sandwich Panel Machine?

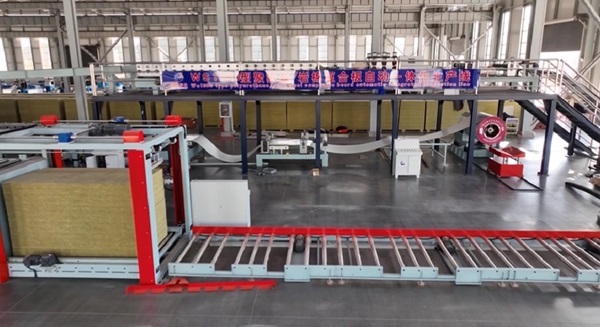

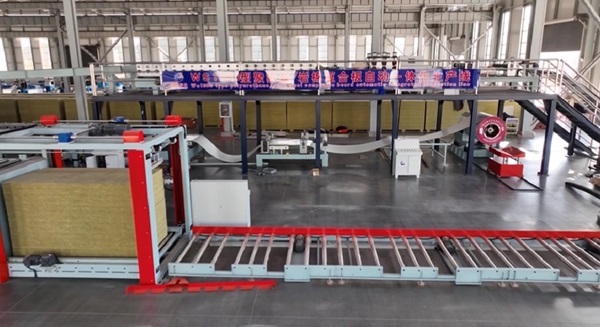

An EPS sandwich panel machine is a specialized manufacturing system designed to produce lightweight yet highly durable panels with expanded polystyrene (EPS) cores. These panels have become essential in a variety of construction and industrial contexts due to their exceptional thermal insulation, fire resistance, and structural stability. In industrial facilities, panels produced by an EPS sandwich panel machine are commonly used for factory walls, cold storage warehouses, cleanrooms, and logistics centers. Their thermal and mechanical properties ensure that controlled environments maintain optimal conditions for sensitive operations. Commercial construction projects also benefit from EPS sandwich panels, as they provide both energy efficiency and sound insulation, making them ideal for office buildings, shopping complexes, and exhibition halls. The versatility of the EPS core allows architects and engineers to design panels of varying thicknesses and facing materials to meet project-specific requirements, making the EPS sandwich panel machine a critical tool for producing tailored building solutions.

EPS Sandwich Panel Machine in Residential and Modular Construction

In residential and modular construction, the EPS sandwich panel machine plays a key role in producing panels for walls, roofs, and partitions. The lightweight yet rigid nature of EPS panels allows for faster construction times while reducing structural loads on foundations. These panels also offer superior insulation, contributing to energy-efficient buildings that meet modern environmental standards. Modular buildings and temporary structures leverage the adaptability of EPS panels for rapid assembly and disassembly, making them ideal for temporary housing, portable offices, or emergency shelters. The EPS sandwich panel machine enables manufacturers to produce panels that are not only consistent in quality but also highly customizable, supporting innovative building designs and modular construction techniques that demand precision and uniformity.

How EPS Sandwich Panel Machine Supports Industrial Sustainability

The EPS sandwich panel machine contributes to sustainable industrial practices by producing panels that enhance energy efficiency in buildings. EPS panels reduce heat transfer and improve thermal regulation, minimizing the need for extensive heating and cooling systems. In industrial plants, EPS panels created by these machines help maintain optimal temperature and humidity, which supports both worker comfort and energy savings. Additionally, the high precision and automation of the EPS sandwich panel machine reduce material waste, as panels are manufactured to exact specifications and with minimal excess. The ability to produce durable, energy-efficient panels aligns with global sustainability trends and allows construction projects to achieve better environmental performance while maintaining quality standards.

Why Jinggong's EPS Sandwich Panel Machine Excels in Application Versatility

Among EPS sandwich panel machine manufacturers, Jinggong is recognized for providing reliable, high-performance solutions tailored to diverse applications. Jinggong's machines feature modular designs that facilitate adjustments for different panel thicknesses, facings, and insulation specifications, making them suitable for industrial, commercial, and residential construction alike. Advanced control systems allow operators to monitor production parameters in real time, ensuring consistent quality and structural integrity across all panels. Durable mechanical components and intelligent automation further enhance the machine's reliability, enabling uninterrupted production for large-scale projects. The combination of flexibility, precision, and robustness ensures that Jinggong's EPS panel machine can meet the evolving demands of modern construction and industrial applications.

The Expanding Reach of EPS Sandwich Panel Machine Applications

Looking ahead, the applications of the EPS sandwich panel machine continue to expand as construction technologies evolve. Prefabricated and modular building techniques are increasingly adopted globally, and EPS panels are becoming the material of choice due to their light weight, high insulation performance, and ease of assembly. Cold storage facilities, data centers, and sustainable urban projects all benefit from EPS panels manufactured with precision on advanced machines. Jinggong's focus on technological innovation and quality assurance positions its EPS sandwich panel machine as a versatile and dependable solution, capable of meeting the demands of both conventional and emerging construction applications.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China