Supply List Of Steel Floor Decking Roll Forming Machine

No. | Name | Qty. | Remark |

1 | Decoiler | 1set |

|

2 | Guiding device | 1set |

|

3 | Forming system | 1set |

|

4 | Cutting system | 1set |

|

5 | Output device | 1set |

|

6 | Hydraulic system | 1set |

|

7 | Electrical system | 1set |

|

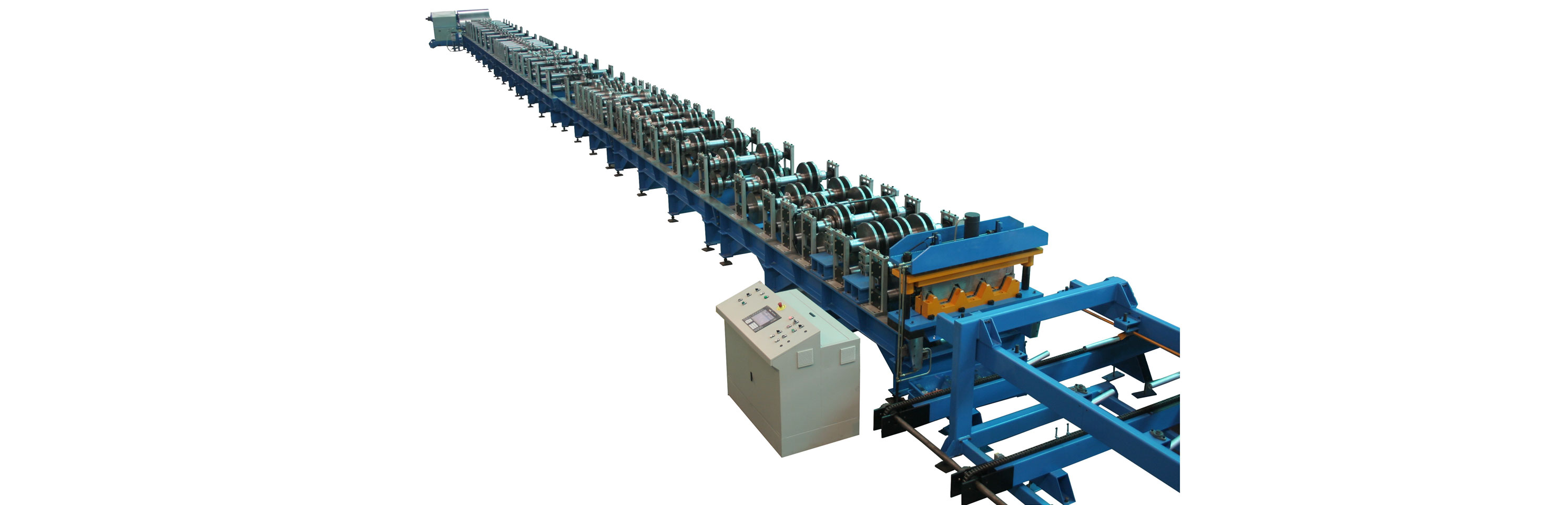

Main components of Steel Floor Deck Roll Forming Machine

The line consists of uncoiler, transmission, roll forming, post-shearing, auto stacker, hydraulic system, controlling system, and etc.

Uncoiler

Cantilever-type fully automatic uncoiler adopts ultrasonic sensor technology and frequency inverter adjustment. The pressing arm hydraulic-driven power is optional. All electrical parts and hydraulic parts are installed inside of uncoiler frame.

Roll Forming

The roll forming system consists of a guiding device, machine base, transmission parts, and roll forming rollers, etc. The cooling and lubricating device is optional.

Post-shearing device

The post-shearing device adopts frame-type hydraulic shearing. The panel is cut stably.

Auto staker

Programming control can calculate the quantities of shear panels. and automatically stacking, moving transversally or lengthways for packing.

Hydraulic system

Hydraulic system is installed inside the machine base. The design is reasonable and compact.

Controller

Mitsubishi PLC Frequency inverter adjustment to realize fully automatic operation.

Operator

The operator can set parameters such as badges, length of panel's quantities in the touch screen

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China