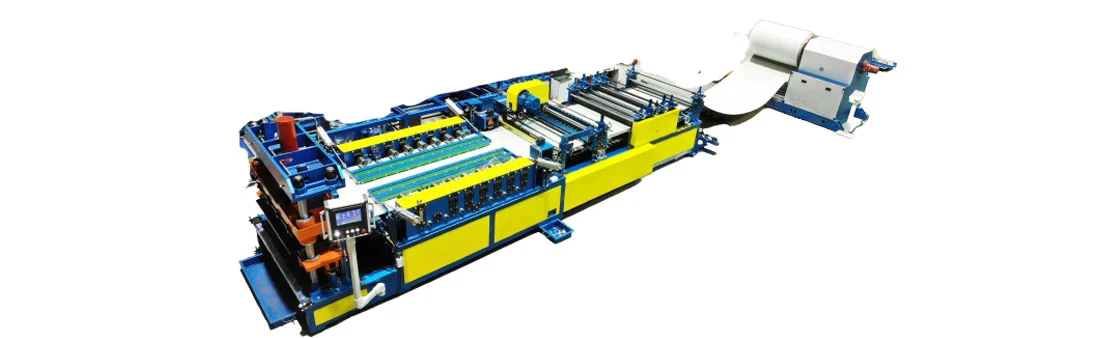

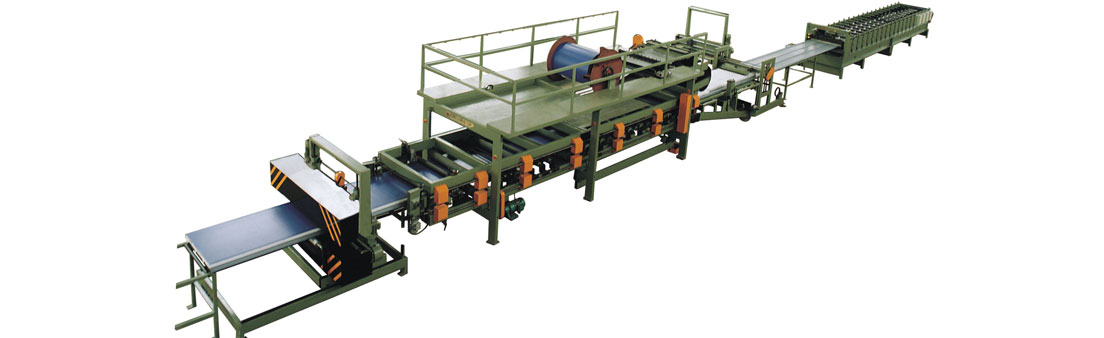

1. Fully Automated Production System

Our continuous sandwich panel production lines are equipped with a fully automated system that integrates various stages of production, including decoiling, roll forming, foaming, lamination, cutting, cooling, stacking, and packaging. This automation minimizes human intervention, reduces labor costs, and ensures consistent product quality. Advanced PLC control systems and digital servo technologies facilitate precise control over the entire production process.

2. High-Speed and High-Capacity Output

Designed for large-scale operations, our production lines offer high-speed capabilities, with adjustable production speeds to accommodate varying project requirements. The continuous nature of the line allows for uninterrupted production, significantly increasing output and meeting the demands of large construction projects.

3. Advanced Foaming and Laminating Technology

Our production lines incorporate high-pressure foaming systems that ensure precise mixing and injection of foam materials, achieving uniform density and thickness across panels. The double belt laminating system applies controlled pressure and heat, facilitating the curing process and ensuring strong adhesion between the foam core and metal facings.

4. Precision Cutting and Sizing

Equipped with automated cutting systems, our production lines provide precise and clean cuts to the desired panel lengths without interrupting the continuous operation. This capability allows for high customization, accommodating various panel sizes and specifications to meet diverse construction needs.

5. Efficient Cooling and Stacking Systems

Post-production, panels are transferred to cooling conveyors that ensure uniform cooling, preventing warping and maintaining dimensional stability. Our automated stacking systems then arrange the cooled panels efficiently, readying them for packaging and shipment, thereby optimizing the overall workflow.

6. Energy-Efficient and Environmentally Friendly Design

Incorporating energy-saving features, our production lines utilize advanced insulation technologies and efficient heating systems to minimize energy consumption. Additionally, the use of environmentally friendly foaming agents aligns with global sustainability standards, reducing the ecological footprint of the manufacturing process.

7. Customization and Versatility

Our production lines are designed with flexibility in mind, capable of producing a wide range of sandwich panels with varying core materials such as polyurethane (PU), polyisocyanurate (PIR), mineral wool, and expanded polystyrene (EPS). This versatility allows manufacturers to cater to diverse market demands, from cold storage facilities to residential and commercial buildings.

8. Integrated Quality Control Systems

To ensure the highest standards of quality, our production lines are equipped with integrated quality control systems that monitor parameters such as foam density, panel thickness, and adhesive application in real-time. Automated fault detection and parameter adjustments help maintain consistent product quality throughout the production cycle.

By incorporating these advanced features, our continuous sandwich panel production lines provide manufacturers with the tools needed to produce high-quality, cost-effective, and customizable panels that meet the evolving needs of the construction industry.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China