Rockwool Sandwich Panel Production Line: The Core Strength of Building Insulation Material Production

In the modern construction industry, as people continuously demand higher performance for building energy efficiency, fire safety, and other features, rock wool sandwich panels have become a widely used premium material for insulation, heat preservation, and fire protection. The rockwool sandwich panel production line is the key equipment for producing these high-performance materials. Its technical level and production efficiency directly affect the quality and market supply of rock wool sandwich panels.

Composition of Rockwool Sandwich Panel Production Line

The rockwool sandwich panel production line usually consists of several key parts, working collaboratively to achieve efficient transformation from raw materials to finished products. The main components include the raw material preparation system, steel plate processing system, rock wool treatment and filling system, composite and forming system, cutting and sizing system, and packaging and warehousing system.

Technical Advantages of Rockwool Sandwich Panel Production Line

High Automation

Advanced automation control systems, such as integrated linkage systems, centralize all control points at the main control center. This allows for parameter linkage and fault self-diagnosis across the entire line, as well as remote control. This not only improves production efficiency but also reduces labor input and human resource consumption, diminishing the impact of human factors on product quality. For instance, some high-end production lines require only 5-6 operators for full operation.

Production Flexibility

The production line can be configured in various setups according to customer requirements. By selecting different combinations and configurations and making simple transitions, it can conveniently automate the production of different types of sandwich panels. The core layer can be made of different materials such as polyurethane, rock wool, or glass wool, meeting diverse market needs.

Stable Product Quality

The production line adopts a modular design with well-functioning main units. It ensures stable and reliable quality, has low component wear, and incurs low maintenance costs. Additionally, there are strict production processes and quality control protocols from raw material inspection to the final product's release, ensuring the product meets high standards.

Energy Efficiency and Environmental Protection

The production line is designed for high power yet low energy consumption, with quick response actions, and low energy use—for example, some production lines use only 40% of the energy compared to similar products. Moreover, its built-in energy-saving and environmental designs allow it to ramp up production without the need for additional insulated rooms or environmental heating, reducing environmental impact.

Market Application and Future Prospects of Rockwool Sandwich Panel Production Line

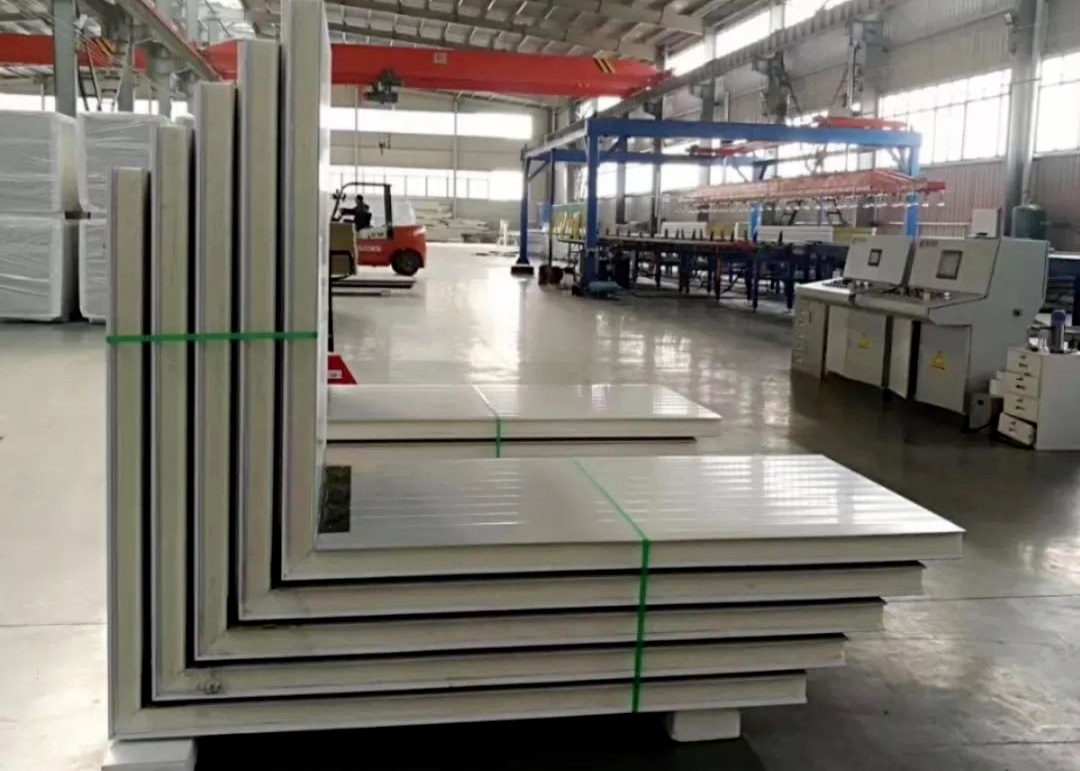

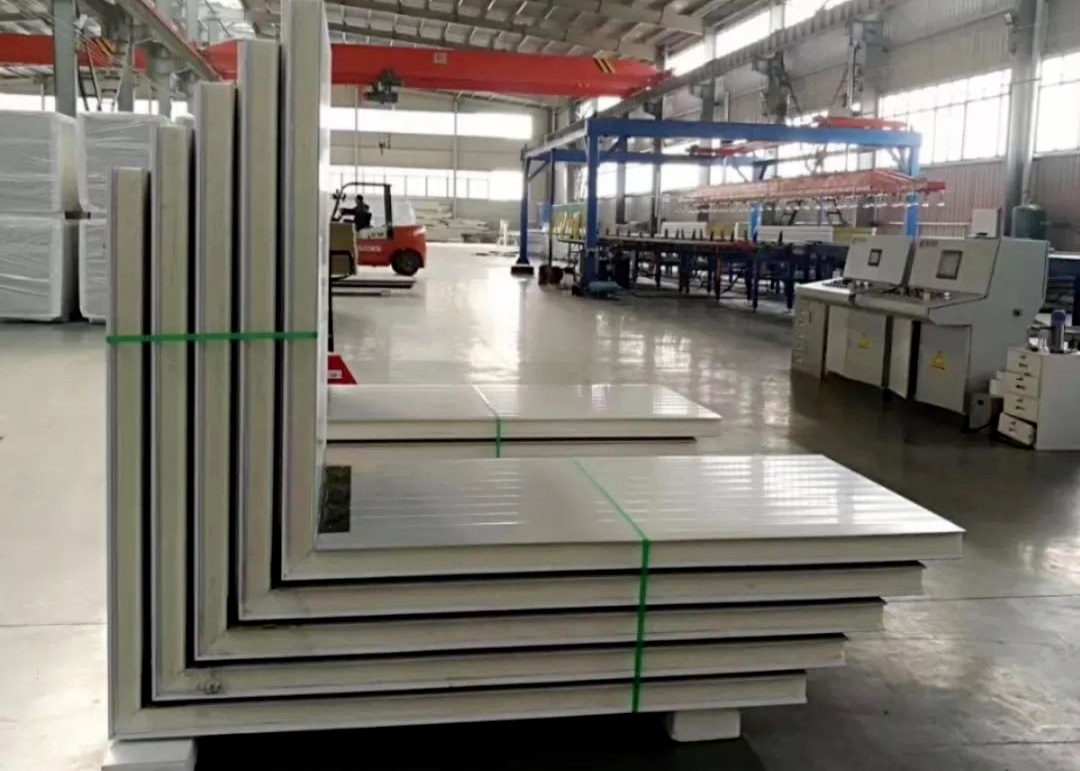

Rock wool sandwich panels, recognized for their excellent fire resistance, insulation, soundproofing, and waterproof properties, are widely used in steel structure buildings, warehouses, factories, cold storage, clean rooms, and other places' exterior walls and roofs.

As the construction industry continuously elevates its requirements for energy efficiency, environmental protection, and fire safety, the market demand for rock wool sandwich panels is steadily growing, opening up a vast developmental horizon for rockwool sandwich panel production lines.

On one hand, more enterprises are investing in advanced rockwool sandwich panel production lines to increase capacity and product quality, enhancing their market competitiveness. On the other hand, technological innovations will continuously propel the production lines toward higher automation, intelligence, and energy efficiency, meeting the market demand for high-quality, diversified rock wool sandwich panels.

Performance Advantages of JINGGONG Rockwool Sandwich Panel Production Line

High production efficiency, able to meet market demands.

High product quality, with uniform density and stable quality, offering excellent insulation and fire resistance.

Low production cost, high degree of automation, effectively reducing labor costs and minimizing raw material waste.

The rockwool sandwich panel production line plays a crucial role in the construction industry by manufacturing quality rock wool sandwich panels. Its advanced technology, efficient production capabilities, and broad market prospects will help drive the construction industry towards a greener, safer, and more energy-efficient future.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China