As the main component in precast concrete components, the assembly part, connection, combination of cast-in-place reinforced Concrete structure, PC component based on component processing unit factory production of finished Concrete members.

One machine can not only produce one size, it depends on the machine designing.

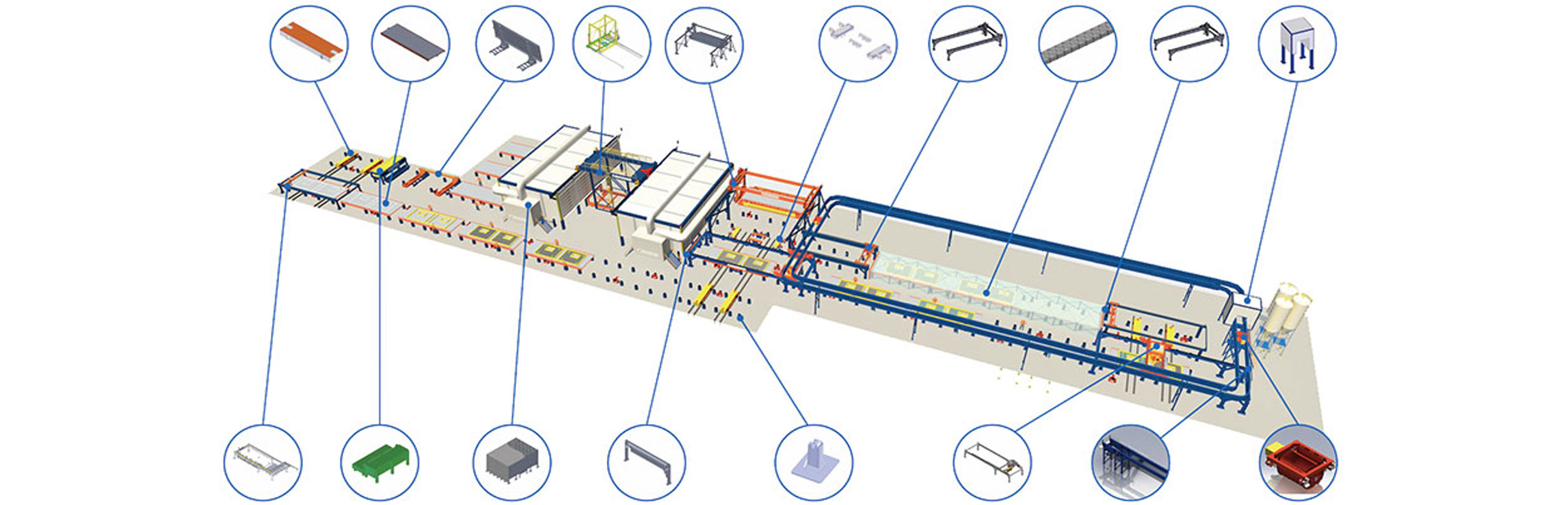

The advantages and characteristics of Precast Concrete Panel Production Line:

1. When making precast concrete panels, it can reduce resources, energy consumption and environmental pollution.

2. It can improve the quality of building product, engineering and safety performance (seismic resistance).

3. Speed up the schedule of construction and shorten the construction cycle.

4. Reduce labor intensity and labor cost, it is the only way to transform and upgrading of Chinese construction industry.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China