Planning of Rockwool Production Line: Creating an Efficient, Green, and Intelligent Production System

Against the backdrop of the continuous growth in the demand for building energy conservation and industrial insulation, rock wool, as a green building material with fireproof, insulation, and soundproof properties, has broad market prospects. A scientific and reasonable rockwool production line planning is key to ensuring product quality, reducing production costs, and achieving sustainable development. This article outlines specific steps and key points.

Preliminary Preparation

Market Research: Understand the market demand, competition, and development trends of rock wool products to determine the target market and product positioning.

Plant Site Selection: Choose a suitable plant location by considering factors such as raw material supply, traffic convenience, energy supply, environmental protection requirements, and labor resources.

Fund Preparation: Estimate the construction funds based on the scale of the rockwool production line and equipment selection, and raise funds through various channels to ensure the smooth progress of the project.

Process and Equipment Selection

Process Selection: The common rock wool production processes currently include the centrifugal method and the pendulum method. The centrifugal method has high production efficiency and stable product quality; the rock wool products produced by the pendulum method have more uniform fiber arrangement and better performance. The appropriate process can be selected based on product positioning.

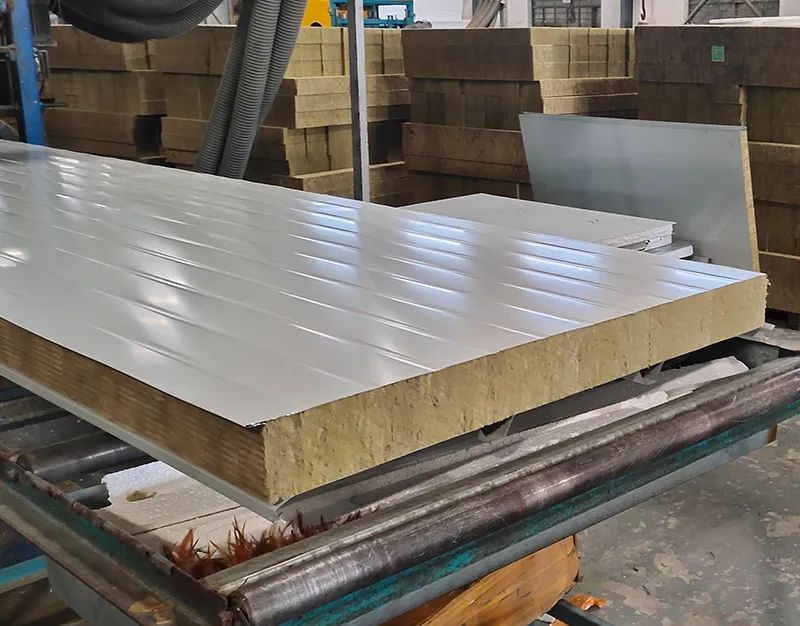

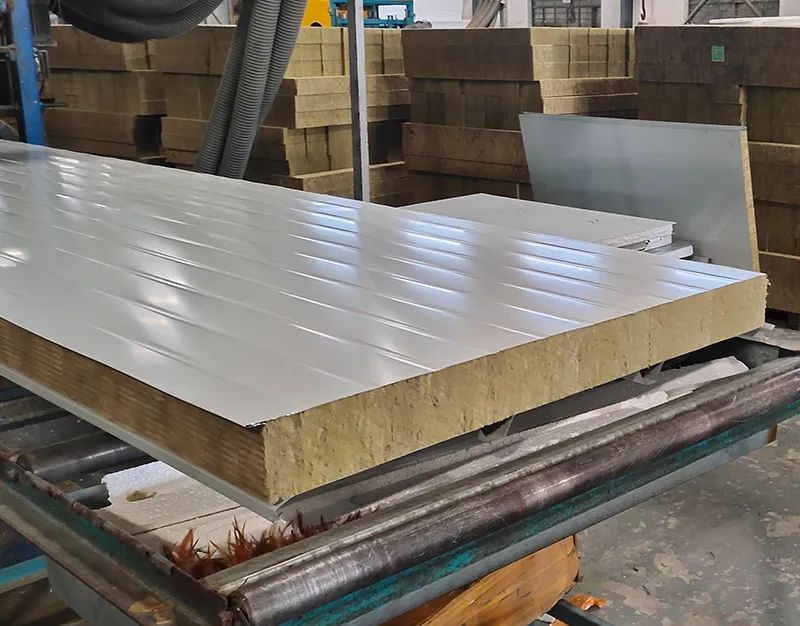

Equipment Selection: Choose supporting production equipment based on the selected process, such as furnaces, centrifuges, pendulum cotton machines, curing ovens, cutting equipment, etc. It is crucial to select reliable, advanced, and highly automated equipment to improve production efficiency and product quality.

Plant Design and Construction

Plant Layout: Plan the functional areas such as raw material zone, production zone, finished product zone, equipment maintenance zone, and office zone reasonably according to the production process flow to ensure smooth material transportation and efficient and orderly production processes.

Plant Construction: Carry out the structural design and construction of the plant according to equipment installation and production process requirements, meeting requirements for load-bearing, ventilation, lighting, fire prevention, and explosion protection. Consider future expansion needs as well.

Installation and Commissioning of the Rock Wool Production Line

Equipment Installation: Follow the equipment installation manual strictly for equipment installation and commissioning, ensuring the accuracy and stability of the installations. Pay attention to the connections and cooperation between pieces of equipment, as well as the installation quality of electrical and pipeline systems during the installation process.

System Commissioning: After the equipment installation is complete, perform single-machine debugging and linked debugging. During the debugging process, adjust and optimize the equipment operating parameters and production process parameters to ensure the rockwool production line meets design requirements.

Personnel Training and Production Preparation

Personnel Training: Conduct systematic training for production operators, technical staff, and management personnel to familiarize them with production processes, equipment operation, quality control, and safety management knowledge and skills.

Production Preparation: Upon completion of the rockwool production line commissioning, conduct trial production. During trial production, comprehensively inspect and evaluate product quality, production efficiency, equipment operation, and other aspects; promptly resolve any issues that arise. Meanwhile, prepare for raw material procurement, product sales, after-sales service, and other aspects to ensure smooth operation after formal production begins.

Environmental Protection and Safety Facilities Construction

Environmental Protection Facilities: Build supporting environmental protection facilities for waste gas treatment, wastewater treatment, and waste residue treatment to ensure that pollutants generated during production are discharged up to standards, reducing environmental impact.

Safety Facilities: Install safety protection devices, fire protection facilities, ventilation facilities, and develop comprehensive safety management systems and operation procedures. Enhance employee safety training to ensure safety in the production process.

The planning of the rockwool production line is a systematic project. Through scientific layout, technological innovation, and green development, it is possible to create an efficient and stable production system that enables enterprises to gain a competitive edge in an aggressive market. This provides reliable material support for building energy conservation and industrial insulation.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China