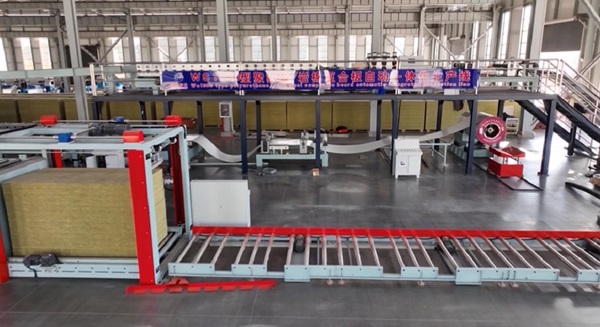

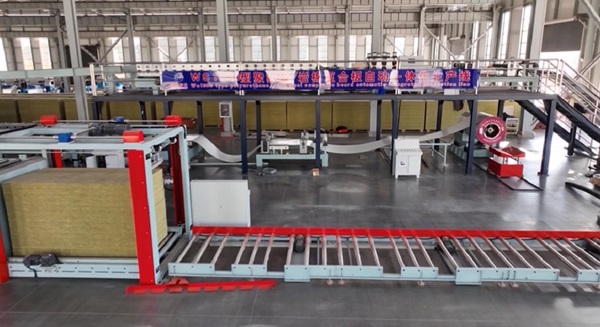

Essential Maintenance Guide for EPS Sandwich Panel Production Line

Modern manufacturing of insulated building materials relies heavily on well-maintained EPS Sandwich Panel Production Line to ensure consistent quality and operational efficiency. Jinggong's advanced machinery requires systematic care to maximize its lifespan and maintain peak performance. Proper maintenance not only prevents unexpected downtime but also safeguards the precision engineering that makes these production lines so valuable to construction material manufacturers worldwide.

Daily Operational Checks and Cleaning Procedures

The foundation of an effective maintenance program for EPS Sandwich Panel Production Line begins with thorough daily inspections. Operators should examine the roll forming stations for any metal debris accumulation that might affect panel profiles, while the EPS feeding system requires verification of smooth material flow. Adhesive application nozzles demand particular attention - clogged spray heads can lead to uneven bonding and defective panels. A disciplined cleaning routine that includes vacuuming EPS particles from conveyor belts and wiping down sensors helps maintain the line's accuracy. Jinggong's systems benefit from these simple yet crucial practices that prevent minor issues from escalating into major repairs.

Lubrication Strategies for Moving Components

A EPS sandwich panel production line contains numerous high-precision mechanical parts that depend on proper lubrication for smooth operation. The roll forming section requires specialized grease application to its gear reduction systems and guide rollers, while conveyor chain lubrication should follow manufacturer-recommended intervals. Hydraulic systems in pressing stations need regular oil level checks and viscosity testing. What separates adequate lubrication from optimal practice is the use of condition-monitoring techniques - vibration analysis and thermal imaging can identify components needing attention before visible wear occurs. These proactive measures significantly extend the service life of critical production line elements.

Electrical System Maintenance vs. Mechanical Upkeep

While mechanical components often receive primary maintenance focus, the electrical systems in EPS Sandwich Panel Production Line demand equal attention. Control cabinets benefit from periodic inspection for loose connections and proper ventilation, while servo motor encoders require cleaning to maintain positioning accuracy. Contrast this with mechanical maintenance - where grease and replacement parts dominate - electrical upkeep emphasizes cleanliness and connection integrity. Frequency inverters need particular care as they regulate the precise speeds essential for synchronized panel production. The balanced attention to both mechanical and electrical systems distinguishes comprehensive maintenance programs from insufficient ones, ensuring consistent panel quality across all production runs.

Seasonal Adjustments for Consistent Performance

Environmental factors significantly impact EPS Sandwich Panel Production Line, necessitating seasonal maintenance adaptations. Summer months may require additional cooling for hydraulic systems, while winter operations often benefit from preheating adhesives to maintain optimal bonding properties. Humidity control becomes particularly important for EPS material storage areas to prevent moisture absorption that could affect panel quality. Jinggong's equipment includes various environmental compensation features, but these work best when combined with seasonal maintenance awareness from operators. Checking and adjusting roller pressures in temperature extremes helps maintain dimensional stability in finished panels throughout changing seasons.

Long-Term Component Replacement Planning

Strategic planning for wear parts replacement forms a crucial aspect of EPS sandwich panel production line maintenance. Creating a replacement schedule for high-wear items like cutting blades, forming rolls, and conveyor belts prevents unplanned downtime. Monitoring production metrics helps predict when components will reach their operational limits - for instance, tracking linear meters produced can indicate when forming rollers may need refurbishment. Jinggong's modular design philosophy simplifies these replacements, allowing quick swaps of wear parts without extensive line disassembly. Keeping an inventory of critical spares ensures minimal disruption when scheduled replacements occur, maintaining consistent production flow and panel quality over the equipment's lifetime.

Implementing this comprehensive maintenance approach for EPS Sandwich Panel Production Line protects manufacturers' investments and ensures continuous output of high-quality building materials. The combination of daily attention, proper lubrication, balanced system care, environmental awareness, and proactive replacement planning creates a maintenance ecosystem that supports Jinggong machinery's full potential. Manufacturers who commit to these practices gain competitive advantages through superior product consistency and minimized production interruptions - crucial factors in today's demanding construction materials market.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China