The Future of Insulation Manufacturing: Advancing With the Rock Wool Production Line

Definition of a Rock Wool Production Line

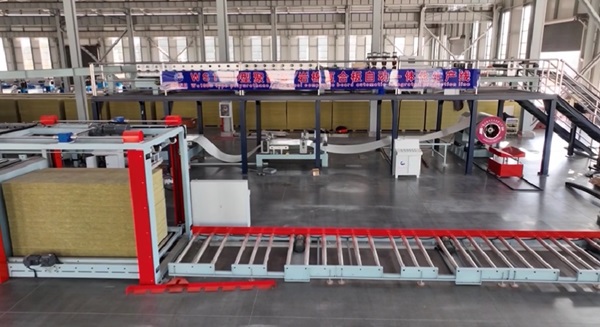

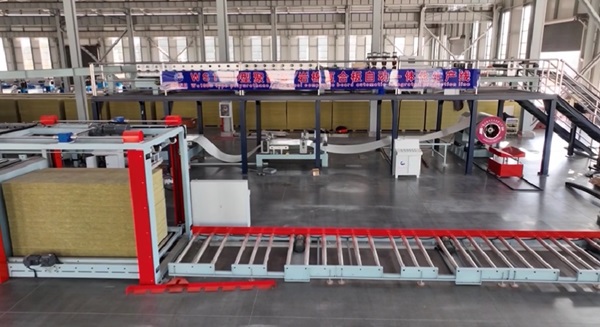

A rock wool production line is an advanced manufacturing system designed to produce rock wool insulation panels with exceptional precision and consistency. The process begins with natural basalt or other high-quality minerals that are melted at extremely high temperatures and then spun into fine fibers. These fibers are combined with binding agents and shaped into layers that form durable insulation materials. In modern facilities, the rock wool production line integrates automated feeding, melting, fiber-forming, curing, and cutting systems to ensure continuous production with minimal human intervention. The final rock wool panels possess excellent fire resistance, sound absorption, and thermal insulation properties, making them a preferred choice for industrial and commercial building applications. With its continuous operation and intelligent control systems, the production line maximizes efficiency while maintaining the structural integrity and uniform density of each panel produced.

The Core Advantages of a Modern Rock Wool Production Line

The rock wool production line delivers a range of technical and operational benefits that make it indispensable in the insulation industry. Its automation ensures precise control over every production stage, from raw material feeding to fiber formation and curing, guaranteeing uniform product quality. The continuous lamination and cutting systems maintain dimensional accuracy, enabling large-scale production without compromising performance. One of the key strengths of this equipment lies in its environmental adaptability—modern rock wool production lines are designed to minimize waste, optimize energy usage, and comply with global environmental standards. The end products are lightweight yet strong, providing excellent thermal and acoustic insulation. These qualities make rock wool panels ideal for wall cladding, roofing, and industrial insulation systems where fire resistance and energy efficiency are critical. By combining advanced engineering and digital control, the rock wool line has set new benchmarks for productivity and product reliability.

Why Is the Rock Wool Production Line Essential for Energy-Efficient Construction?

As global construction trends shift toward energy efficiency and sustainability, the rock wool production line plays an increasingly vital role. Rock wool, as a non-combustible and recyclable material, meets the rising demand for green building materials that contribute to energy conservation and occupant safety. Buildings insulated with rock wool panels exhibit significantly reduced energy consumption for heating and cooling, creating more sustainable structures. The production line's continuous operation ensures consistent quality, allowing architects and engineers to design high-performance envelopes for modern infrastructure. In addition, the durability and water resistance of rock wool panels make them suitable for extreme climates, preventing heat loss while maintaining interior comfort. Through continuous innovation and material optimization, the rock wool production line not only supports sustainable development goals but also enhances the overall performance and lifespan of buildings worldwide.

The Future Development of Rock Wool Production Line Technology

Looking forward, the rock wool production line is expected to evolve alongside advancements in automation, energy recovery, and digitalization. Future systems will incorporate more intelligent process controls that monitor temperature, viscosity, and fiber thickness in real time, ensuring optimal efficiency and minimal waste. AI-driven diagnostics will help predict maintenance needs, reducing downtime and improving operational sustainability. At the same time, improvements in material science will allow rock wool panels to achieve even higher thermal efficiency and durability. The integration of environmentally friendly production technologies will further reduce emissions, aligning the rock wool industry with global green manufacturing standards. As one of the most reputable equipment manufacturers, Jinggong continues to pioneer innovations that redefine insulation technology and support global efforts toward sustainable and energy-efficient construction.

What Makes Jinggong's Rock Wool Production Line Different from Others?

Among the world's rock wool production line manufacturers, Jinggong stands out for its innovation, precision engineering, and commitment to technological advancement. The company integrates advanced automation, intelligent control, and modular design into its production systems, allowing flexible configuration according to specific customer requirements. Jinggong's equipment ensures efficient fiber distribution, uniform curing, and high-speed lamination, producing panels that meet strict international standards. The integration of servo control and digital monitoring enables precise synchronization across all production stages, ensuring consistent thickness and density. Moreover, Jinggong's engineering expertise allows for customization of line capacity, panel dimensions, and insulation performance to suit diverse industrial and construction needs. With years of experience in high-tech equipment manufacturing, Jinggong continues to lead the industry by delivering rock wool production lines that combine stability, reliability, and intelligent automation, providing clients worldwide with superior-quality insulation manufacturing solutions.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China