Rockwool Production Line: Advanced Solutions by Jinggong

Innovation and Expertise in Specialized Equipment

Jinggong Intelligent Building Material Equipment Co., Ltd., a leading Chinese enterprise controlled by Zhongjianxin (Zhejiang) Venture Capital Co., Ltd., has established itself as a global pioneer in specialized machinery. Founded in 1968, the company underwent shareholding reform in 2000 and became successfully listed in 2004. Over more than five decades, Jinggong has remained committed to advancing industrial technology, focusing on two "Carbon" industries—carbon fiber equipment and carbon neutral (new energy) equipment—while also consolidating its leadership in intelligent building material machinery and intelligent textile machinery. With strong research and development capabilities, the company has consistently been the promoter of industrial upgrading in China, offering reliable and innovative solutions to industries worldwide.

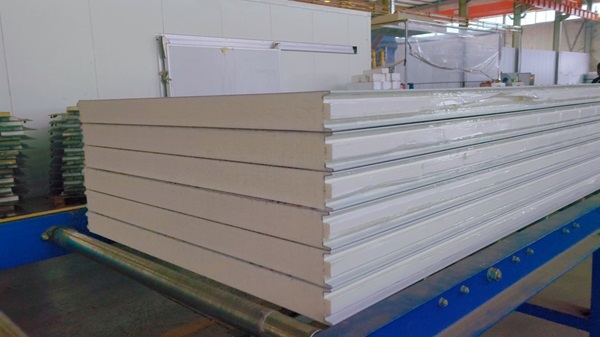

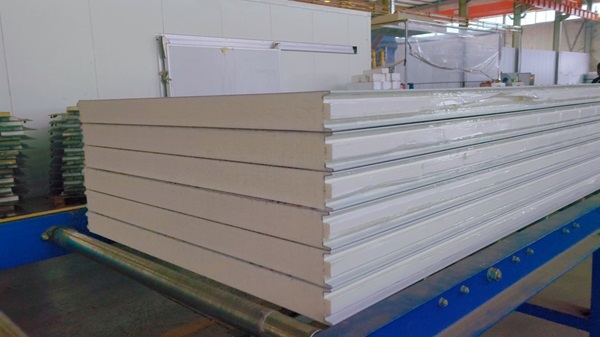

Rockwool Production Line for Sustainable Building Solutions

One of Jinggong's core strengths lies in its ability to provide complete and highly efficient rockwool production line systems. Rockwool, a material made from natural basalt, is widely used in modern construction for insulation, soundproofing, and fire resistance. In response to the growing demand for energy-efficient and environmentally friendly building materials, Jinggong has invested its expertise in engineering advanced continuous production lines for rockwool sandwich panels. These production lines are designed with intelligent automation, precise control, and high efficiency, enabling manufacturers to produce panels that meet strict international standards while also ensuring cost-effectiveness. By leveraging decades of technological innovation, Jinggong's rockwool machinery supports the global construction industry in its move toward sustainable and energy-efficient building practices.

Technology, R&D, and Global Recognition

As a national key high-tech enterprise, Jinggong Technology has earned recognition not only in China but also on the global stage. The company has developed more than 150 types of high-tech and high-value-added products and holds over 400 national patents. Its R&D team, composed of highly skilled experts, continuously integrates advanced technology into the rockwool production line, ensuring efficiency, precision, and product quality. This commitment to innovation reflects the company's philosophy of "Professionalism, Focus, and Leading Technology." Jinggong's equipment has been exported to more than 100 countries and regions, reinforcing its status as an international leader in specialized machinery for building materials. With a focus on automation, energy savings, and intelligent production systems, the rockwool machinery from Jinggong provides construction companies with a reliable foundation for large-scale, modern projects.

Rockwool Production Line vs. Traditional Insulation Manufacturing

While rockwool production is a specialized process, it brings clear advantages compared to traditional insulation materials. Jinggong's continuous production line ensures consistent panel quality, reduced labor costs, and higher production speed. The table below highlights the main differences between a rockwool production line and conventional insulation manufacturing methods:

Aspect | Rockwool Production Line (Jinggong) | Traditional Insulation Manufacturing |

Efficiency | Automated continuous production with high output | Manual or semi-automated, lower productivity |

Product Quality | Uniform density, precise thickness, superior fire resistance | Inconsistent quality, limited fireproofing |

Energy Performance | Excellent thermal insulation and energy saving | Lower insulation performance |

Sustainability | Utilizes natural basalt, eco-friendly process | Often dependent on synthetic materials |

Market Competitiveness | Meets international building material standards | Limited global competitiveness |

This comparison illustrates why Jinggong's rockwool production line has become the preferred choice for construction companies aiming for modern, sustainable, and cost-efficient building projects.

Creating Value Through Innovation and Global Reach

Jinggong Technology's corporate spirit, "Being Brave in Innovation and Striving for Perfection", reflects its mission to continuously improve. By combining advanced technology, innovative management systems, and international collaboration, the company has built an ecosystem that provides customers with not only machinery but also integrated solutions. Its rockwool production line is more than just equipment—it is part of a world-class system that supports intelligent manufacturing, sustainability, and industrial upgrading. With sales prevailing across more than 100 countries, Jinggong has positioned itself as a reliable partner for global clients, committed to delivering leading technology, excellent products, and exceptional service. Looking forward, the company will continue to strengthen its role as a world-class provider of high-end equipment system integration solutions, ensuring that innovation and intelligence shape the future of building material manufacturing.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China