Key Components of EPS Sandwich Panel Production Line

In the modern construction industry, EPS sandwich panel production line have become essential for manufacturing lightweight yet durable insulated building materials. As a leading provider of industrial machinery, Jinggong designs advanced production systems that integrate multiple components to create high-quality EPS (expanded polystyrene) sandwich panels efficiently. Understanding the core elements of these production lines helps manufacturers optimize operations and maintain consistent output quality.

Core Material Processing Systems

At the heart of every EPS sandwich panel production line lies the expanded polystyrene processing unit, where raw EPS beads are expanded and molded into insulation boards. The system includes precision cutting mechanisms that ensure dimensional accuracy before panels enter the bonding phase. Synchronized conveyors transport the rigid foam cores through different processing stages while maintaining structural integrity. Jinggong's equipment incorporates automated quality checks in this section to detect irregularities in density or thickness before panels proceed downstream.

Continuous Metal Sheet Feeding and Forming

High-speed EPS sandwich panel production line from Jinggong rely on automated coil decoilers that feed metal sheets into roll forming machines with precision. The forming process shapes the metal into the desired panel profile—whether trapezoidal, sinusoidal, or custom designs—while ensuring smooth edges for optimal bonding. Advanced tension control systems prevent material slack or stretching, which could affect panel quality. Some manufacturing setups use pre-painted coils to eliminate additional finishing steps later in production, streamlining workflow efficiency.

Adhesive Application and Bonding Mechanisms

A critical component of any EPS sandwich panel production line is the adhesive dispensing system, which applies high-strength bonding agents uniformly across both EPS and metal surfaces. Modern lines use programmable spray nozzles or roller coaters that adjust glue distribution based on panel specifications. The bonding station typically consists of a double-belt press that applies controlled pressure and heat to cure adhesives while maintaining panel alignment. Jinggong's designs optimize press timing and temperature settings to improve bond strength without compromising production speed.

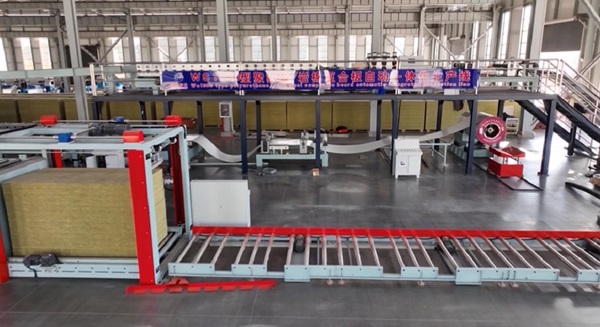

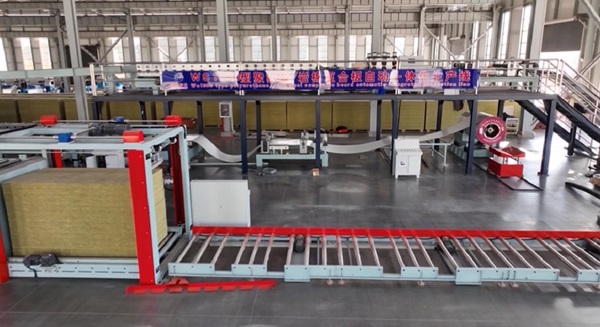

Traditional vs. Automated Panel Handling Solutions

When comparing older and newer EPS sandwich panel production line, automation becomes the key differentiator. Traditional lines often require manual intervention between the lamination and curing stages, leading to inconsistencies. In contrast, Jinggong's fully automated conveyors transport panels seamlessly from forming to quality inspection while maintaining precise positioning. Robotic stacking arms replace manual handling at the end of the line, significantly reducing labor costs and error rates. While some manufacturers maintain semi-automated operations for flexibility, fully automated systems typically offer better throughput and long-term cost efficiency for large-scale production.

Final Processing and Quality Control

Before packaging, assembled EPS sandwich panels undergo finishing steps that include edge trimming, end-cutting, and surface inspection. Vision-based quality control systems scan panels for defects such as delamination, uneven edges, or coating flaws. Automated stacking and bundling mechanisms then organize finished panels for shipment, with options for strapping or protective wrapping depending on customer requirements. By integrating these final components, Jinggong's production lines ensure finished EPS sandwich panels meet structural integrity and aesthetic standards for various construction applications.

Jinggong's EPS sandwich panel production line exemplify industrial efficiency by merging automated precision with modular functionality. Each component, from coil decoiling to robotic stacking, contributes to streamlined manufacturing that maximizes output without sacrificing quality. For builders seeking sustainable, thermally efficient materials, investing in a well-integrated EPS production line provides long-term advantages in both performance and profitability.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China