Innovation and Energy-Saving Approaches in Rockwool Production Lines

The Importance of Energy Efficiency in Rockwool Manufacturing

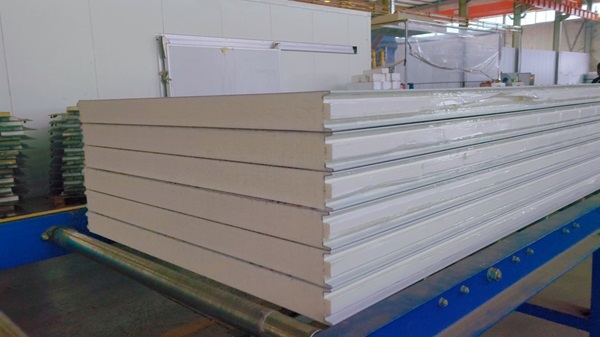

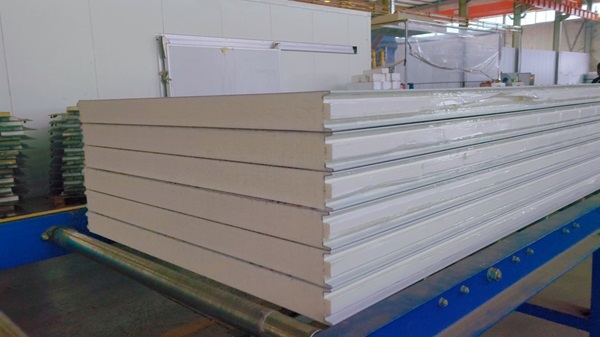

Rockwool, known for its outstanding thermal insulation and fire resistance, has become a preferred material in the construction industry. The efficiency of the rockwool production line plays a decisive role in ensuring not only product quality but also sustainable manufacturing. As the construction sector places greater emphasis on environmental protection and carbon reduction, manufacturers are under pressure to adopt energy-saving approaches. A well-designed production line minimizes energy consumption, optimizes raw material use, and reduces emissions while maintaining the structural integrity of rockwool panels. This balance between quality and efficiency reflects the future direction of the industry.

How Modern Rockwool Production Lines Achieve Energy Savings

Energy efficiency in a rockwool production line is largely achieved through automation and precision control. Modern systems integrate advanced heating technologies, intelligent feeding systems, and optimized curing processes. Automated controls ensure that the exact amount of energy is applied where necessary, preventing waste and overuse. Furthermore, smart monitoring systems analyze temperature, airflow, and material distribution in real time, ensuring uniform panel quality while reducing unnecessary energy costs. These improvements create a production process that is both economical and environmentally responsible, aligning with global standards for sustainable manufacturing.

Comparing Traditional and Modern Rockwool Production Lines

The difference between traditional production systems and modern automated solutions demonstrates how innovation contributes to sustainability.

Aspect | Modern Rockwool Production Line | Traditional Rockwool Production Line |

Energy Consumption | Optimized heating, lower energy use | High energy demand, less efficient |

Automation Level | High automation, minimal manual input | Heavy reliance on manual processes |

Material Utilization | Precise feeding reduces waste | Higher waste due to inaccuracy |

Environmental Impact | Reduced emissions, eco-friendly | Higher emissions, less sustainable |

Cost Efficiency | Lower long-term costs | Higher operational costs |

This comparison shows that the transformation from traditional to modern systems is not just about production speed but also about sustainable growth. By minimizing waste and energy use, modern production lines allow companies to stay competitive while addressing ecological responsibilities.

Jinggong's Role in Driving Innovation

With more than 50 years of expertise in specialized equipment manufacturing, Jinggong has consistently advanced the standards of intelligent building material production. Its rockwool production line integrates energy-efficient systems designed to optimize resource use without compromising quality. Through close collaboration with research institutions and international partners, Jinggong has developed solutions that reflect both technological leadership and environmental awareness. This approach helps customers achieve efficient, reliable, and sustainable production processes, making Jinggong a trusted partner in the field of high-end equipment manufacturing.

Toward a Sustainable Future in Rockwool Manufacturing

Innovation in energy-saving production methods is not an option but a necessity for the future of the construction materials industry. A modern rockwool production line demonstrates how technology can reduce costs, minimize emissions, and deliver superior performance. Manufacturers who adopt such systems gain long-term advantages, including reduced operational expenses and enhanced competitiveness in global markets. By providing advanced equipment solutions, Jinggong contributes to shaping a sustainable future where efficiency and environmental responsibility go hand in hand, ensuring that rockwool production continues to meet the demands of modern architecture and green development goals.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China